LinaPunch

C purlines of 26 meters and over...

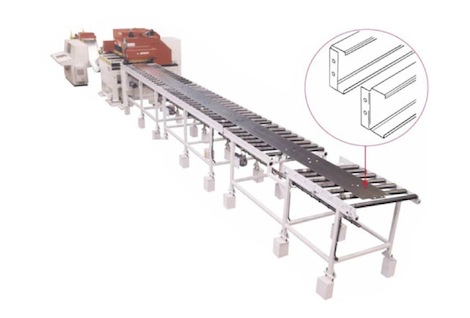

Single LINAPUNCH (up to 522 mm wide) or dual LINAPUNCH (up to 1020 mm) is now the essential unit to punch extra long Z or C purlins and metal building framework parts. The maximum length realized is 26 meters. Of course, we do not go further due to transportation capacity!

Single LINAPUNCH (up to 522 mm wide) or dual LINAPUNCH (up to 1020 mm) is now the essential unit to punch extra long Z or C purlins and metal building framework parts. The maximum length realized is 26 meters. Of course, we do not go further due to transportation capacity!

Single LINAPUNCH, equipped with its 12 tools, and dual LINAPUNCH, equipped with its 24 tools, achieve punching, notching and all other operations, whatever their position on sheet metal. After punching, parts are introduced into the PORVOT PROFIL roll-forming machine and continuously formed.

Accuracy:

The principle of numerical measurement, from the beginning to the end of the part, allows accuracy of about +/- 0.2 mm, never reached in this field, whatever the part length is.

The principle of numerical measurement, from the beginning to the end of the part, allows accuracy of about +/- 0.2 mm, never reached in this field, whatever the part length is.

Linking Programme:

The line is programmed to link different parts without material waste, thus allowing production of complete framework without intermediate storage

The line is programmed to link different parts without material waste, thus allowing production of complete framework without intermediate storage

The line consists of:

2350 C uncoiler. Charge: 2500 kg

1576 CVV straightener. Capacity: 400 x 3 mm

1125 D - DNC MICROFEED teeder

YT 12D LINAPUNCH

1727 D Shear

2350 C uncoiler. Charge: 2500 kg

1576 CVV straightener. Capacity: 400 x 3 mm

1125 D - DNC MICROFEED teeder

YT 12D LINAPUNCH

1727 D Shear

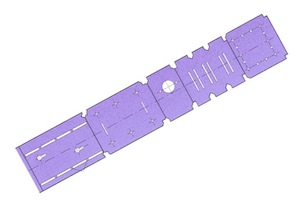

The figure (left) shows linking of parts with multiple operations: punching, nibbling, notching.

Using a microjunction tool on the part enables the production of clusters of miscellaneous parts in a same coil width. Some small attachments keep the cluster together, these attachments are broken during the unfastening operation.

Using a microjunction tool on the part enables the production of clusters of miscellaneous parts in a same coil width. Some small attachments keep the cluster together, these attachments are broken during the unfastening operation.

To Enquire:

CALL: (888) 867-5553

email: info[at]press-equipment.com